I-Elevator Steel Wire Rope Class 8×19

Idatha Yezobuchwepheshe:

| Ububanzi bokuzisholo | Cishe.isisindo | Umthwalo omncane wokuphuka | |||

| 1370 - 1770N/mm2 | 1570N/mm2 | 1770N/mm2 | 1960N/mm2 | ||

| mm | Kg/m | kN | |||

| 8 | 0.26 | 35.8 | 35.7 | 40.3 | 44.7 |

| 9 | 0.33 | 45.3 | 45.2 | 51 | 56.5 |

| 10 | 0.407 | 55.9 | 55.9 | 63 | 69.8 |

| 11 | 0.492 | 67.6 | 67.6 | 76.2 | 84.4 |

| 12 | 0.586 | 80.5 | 80.5 | 90.7 | 100 |

| 13 | 0.688 | 94.5 | 94 | 106 | 118 |

| 14 | 0.798 | 110 | 110 | 124 | 137 |

| 15 | 0.919 | 126 | 127 | 143 | 158 |

| 16 | 1.04 | 143 | 143 | 161 | 179 |

| 17 | 1.18 | 162 | 183 | 203 | |

| 18 | 1.32 | 181 | 204 | 226 | |

| 19 | 1.47 | 202 | 228 | 253 | |

| 20 | 1.63 | 224 | 252 | 279 | |

| 22 | 1.97 | 271 | 305 | 338 | |

| 24 | 2.34 | 322 | 363 | 402 | |

| 26 | 2.75 | 378 | 426 | 472 | |

| 27 | 2.97 | 408 | 460 | 509 | |

| 28 | 3.19 | 438 | 494 | 547 | |

| 29 | 3.43 | 472 | 532 | 589 | |

| 30 | 3.68 | 506 | 570 | 631 | |

| 32 | 4.17 | 572 | 645 | 715 | |

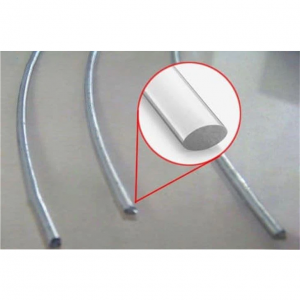

IkheshiIntambo Yensimbi YensimbiIkilasi 8×19

8×19 S + IWRC (1-9-9)

8x19W+IWRC (1-6-6+6)

8x25F+IWRC (1-6-6F+12)

8x26WS+IWRC (1-5-5+5-10)

I-Steel Chemistry:

Kusetshenziswa inhlanganisela yamabanga ensimbi kanye nezinqubo zokwelashwa kokushisa ukuze kukhiqizwe amamaki athambile, aphakathi nendawo naqinile.Ithebula elingezansi libonisa kuphela amakhemikhali ensimbi asetshenzisiwe.

| Ibanga le-Tensile | % Ikhabhoni | % Phosphorus | % IManganese | % I-silicon | % Isibabule |

| Okujwayelekile | 0.45~0,50 | 0.032 | 0.5 ~ 1.00 | 0.10~0.34 | 0.041 |

| Phezulu | 0.59~0.63 | 0.035 | 0.5 ~ 1.10 | 0.10~0.35 | 0.045 |

| Extra-High | 0.65~0,83 | 0.035 | 0.5 ~ 1.10 | 0.10~0.35 | 0.045 |

Lay direction: kwesokudla isandla beka

Okukhethwa kukho kokucela: Okufakwe amagalani/ okungavanisiwe, isandla sokunxele, Ukuqina okukabili, izinga lokugcoba.

Ibanga Lensimbi: I-High Carbon Steel Wire Rod: 40#45#60# 65# 70# 72A# 82B

Isicelo: Elevator

Ukubeka: Isandla sokudla Ukulala njalo (RHRL);Isandla sokudla lang(RHLL);Ukulala okuvamile kwesandla sobunxele (LHRL);Isandla sobunxele lang (LHLL).

Izinto zokupakisha: Izintambo zokhuni, amaphalethi okhuni, iphepha le-Kraft.

Izinga Lomkhakha:

Eyodwa: I-Double steel grade amandla aphindwe kabili, No. 45 steel, No. 65 steel, 1370N/mm2, 1770Mpa,

Okubili: inombolo yensimbi eyodwa, amandla angawodwa, insimbi engu-65, i-1770N/mm2.Izintambo zensimbi ye-elevator ziyi-sisal kanye nezintambo zokwenziwa ze-PPC ngokwezindinganiso zikazwelonke.Ukucaciswa kanye namamodeli wezintambo zezintambo ze-elevator ezinesivinini esikhulu ngu-8*19S+8*7+pp, 8*19S+8*7+1*19

Ngaphansi kwezimo ezijwayelekile, izintambo eziningi zezintambo ezintsha zigcotshiwe ngesikhathi sokukhiqiza, kodwa ngesikhathi sokusetshenziswa, ukulahleka kwamafutha okugcoba kuzoncishiswa.Ngenxa yokuthi ukugcoba akukwazi nje ukuvikela intambo yensimbi ekugqwaleni ngesikhathi sokuthutha nokugcinwa, kodwa futhi kunciphisa ukuguga phakathi kwezintambo, phakathi kwezintambo zezintambo naphakathi kwentambo yocingo kanye ne-traction sheave groove ngesikhathi sokusetshenziswa kwentambo. intambo yocingo, kanye nokusetshenziswa kwezintambo zocingo ezinwetshiwe.Ukuphila isikhathi eside nakho kunenzuzo kakhulu.Ngakho-ke, ukuze unciphise umonakalo wokugqwala nokugqoka entanjeni yocingo, kuyadingeka ukwenza ukuhlolwa kokugcoba.Okokuqala, kubalulekile ukukhetha igrisi yokugcoba ngentambo efanele.I-elevator wire lubricating grease kufanele ibe igrisi ekhethekile yokukhuhlana ene-coefficient ethile yokungqubuzana.Igrisi yokugcoba ngentambo esebenza kahle iyisiqinisekiso esiyisisekelo sokugcina intambo yocingo nokwelula impilo yentambo yocingo.Uma intambo yensimbi isebenza, ingaphakathi linikeza ukungqubuzana kwezintambo ezintathu-ntathu, okudinga ukuthi igrisi yentambo yocingo ibe nezindawo eziqinile zokungena, okungukuthi, i-molecule yamafutha okugcoba evimbela ukugqokwa kugrisi yokugcoba ingangena kunsimbi ngayinye. ucingo.Ngaphezu kwalokho, igrisi yentambo yocingo kufanele futhi ibe nezakhiwo eziqinile zokunamathela.ukuqinisekisa ukuthi inamathela ngokulinganayo entanjeni ngayinye yocingo.Ngokuvamile kunezindlela eziningana zokugcoba nokugcina intambo yocingo.Enye iwukuqaqa intambo yocingo bese uyicwilisa emafutheni okugcoba ngezinga lokushisa elingu-80 kuya ku-100 degrees cishe amahora amabili kuya kwangu-4.Okunye ukuxubha okokugcoba ngqo entanjeni yocingo ngebhulashi.Ukhiye ukwazi kahle indlela yokuxubha kanye nesikhawu.Ngokuvamile, intambo yocingo enobubanzi obungaba ngu-12mm ixutshwa cishe nge-1 kg yamafutha okugcoba njalo ngamamitha angu-40, futhi isikhathi sokuxubha cishe amasonto amabili;enye iwukusebenzisa Isisetshenziswa esikhethekile sokuthambisa ngentambo yocingo sisetshenziselwa ukugcoba intambo yocingo.Le ndlela iyona elula kunazo zonke, kodwa izindleko zemishini ziphezulu.Indlela yokuthambisa ethize kanye nendlela yokugcoba esetshenziswayo kufanele yenziwe ngokuhambisana nezidingo zomkhiqizi wezintambo zocingo.Njengamanje, awamaningi amayunithi okulungisa amakheshi akunaka ngempela ukugcotshwa nokugcinwa kwezintambo zocingo.Amayunithi amaningi abejwayele ukushintsha izintambo zocingo ezintsha ngaphandle kokunaka ukuphathwa kokugcoba.Lesi yisici esisodwa kuphela sezidingo zokuqinisekisa ukusetshenziswa okuphephile kwezintambo zocingo.Ukwengeza, kuyadingeka futhi ukubheka izimo ze-peripheral zentambo yocingo, njengokuguga kwe-traction sheave groove kanye ne-geometry ye-sheave groove ukuqinisekisa ukuthi intambo yocingo ihlale ixhumene kahle ngesikhathi sokusebenza ukuze kuncishiswe ukungqubuzana. .Qinisekisa ukusebenza okuphephile kwekheshi.

Okwesithathu: Indlela yokunquma yempilo yokukhathala yezintambo zensimbi zamakheshi

Ukunqunywa kwempilo yokukhathala kudinga ukusetshenziswa komshini okhethekile wokuhlola ukukhathala kwentambo yensimbi, ngokuhambisana nenqubo kazwelonke evamile ye-GB/T12347-2008 yensimbi yensimbi egoba ukukhathala, noma i-YB/T4288-2012 ikheshi lensimbi yentambo egoba indlela yokuhlola ukukhathala. .Izinga lezintambo zezintambo zekheshi ezivela kubakhiqizi abahlukene lingafaniswa, futhi ikhwalithi ephelele yezintambo zezintambo zekheshi yezinqubo ezahlukene zokukhiqiza nazo zingaqhathaniswa.

Intambo yezintambo ezisekelwe ku-phosphating ezisekelwe ku-phosphating kanye nentambo yekheshi elibushelelezi enobubanzi obufanayo, ukwakheka nokusebenza kwahlolwa ngokulandelana emshinini wokuhlola ukukhathala kwaze kwaba yilapho kuvela intambo yokuqala ephukile, impilo yokukhathala yarekhodwa, kanye nedatha yokuhlola. kuqhathaniswa.Ngokuvamile, ukuphila kokukhathala isikhathi eside, isikhathi eside senkonzo, futhi ziyalingana.Uma impilo yokukhathala iba yinde, iphakamisa ikhwalithi iyonke yentambo yentambo yekheshi.